NEWS

Program Preview | "Powerful Nation, Smart Manufacturing" Column, January 14, 2026: "Driving the Future"

In this issue, the "Powerful Nation, Smart Manufacturing" column recommends "Driving the Future" to you

Automation and intelligence are one of the directions for China's industrial development. However, in this process, we still face many problems. Besides technological innovation, upgrading old production lines is also a challenge we need to address. For example, in the automotive industry, equipment investment is already a significant expense. So, how can they achieve automated upgrading?

It is recommended to watch five minutes in advance

(If the channel broadcast time is adjusted, the new broadcast time shall prevail.)

The automotive industry serves as a crucial yardstick for assessing a country's comprehensive industrial strength during non-war times, reflecting its manufacturing capabilities and technological innovation. In recent years, as China's industrial level has continuously reached new heights, the development of the automotive industry has also ushered in a new chapter. The introduction of new energy vehicles and overtaking on the curve are our latest understandings of the domestic automotive industry. However, many are unaware that although domestic new energy vehicles have entered the international market, China's automotive industry's automation equipment manufacturing sector actually started relatively late, with overall development lagging behind the overall automotive manufacturing process level. Automated production lines are the backbone of the automotive industry. Stamping, as the foremost of the four major automotive manufacturing processes, has always been a manifestation of comprehensive technological strength, with the world's advanced level producing at a rate of more than 15 times per minute. This is no longer just a competition in manufacturing, but also an ultimate contest between countries' industrial systems, innovation ecosystems, and standard discourse power. Faced with difficulties, countless Chinese enterprises have stepped forward, marching towards this peak.

Hao Yuxin, the chairman of Jinan Haozhong Automation Co., Ltd., has been deeply involved in the field of automotive production line automation for nearly three decades. He is well aware of the urgent needs of domestic automobile companies. It is with this mindset that Haozhong, with innovation as its foundation and service as its compass, is moving forward towards the goal of developing domestically produced high-end production lines. At the beginning of its establishment, they set their development direction as high-speed stamping automation equipment systems. After long-term efforts by the team, coupled with joint development of the underlying control logic of high-speed robotic arms with a team of Tsinghua University Ph.D. students, they have overcome technical difficulties one by one and conducted extreme tests repeatedly. In 2014, they developed their first generation of high-speed single-arm robotic arm. Haozhong did not stop there, and in 2018, they successfully developed the second generation of high-speed single-arm robotic arm, with some performance indicators even surpassing the current international level. Instead of stopping, they continue to expand and optimize their products, providing the most suitable automation improvement solutions for domestic enterprises. This is the greatest benefit of domestic production.

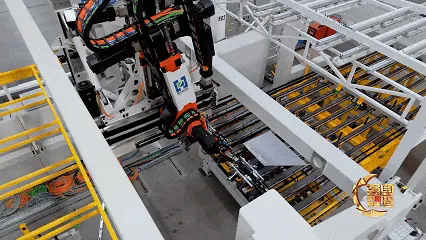

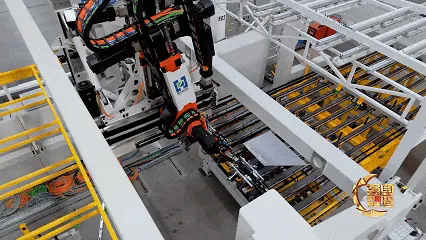

After obtaining the relevant requirements and materials for the Kunshan project, Haozhong quickly returned to the company to conduct discussions. They comprehensively designed the project based on various aspects such as the customer's factory layout, production pace, and product characteristics, striving to come up with the most suitable solution for the customer. During this process, Haozhong's R&D team worked day and night, while continuing to optimize the dynamic model and motion curve trajectory of the robotic arm with a doctoral team from Tsinghua University. They pursued excellence and were determined to successfully fulfill the customer's requirements. On the other hand, Haozhong's core technical team mastered the underlying logic of the press's motion, which was more conducive to achieving the matching between the press and automation as well as the integration of the entire line. They had a deeper understanding of the mutual matching between automation and the press. Ultimately, the customer was moved by Haozhong's sincerity and signed an order in 2020. Haozhong also lived up to expectations, completing the installation and commissioning of the entire line in May 2021, with all operational indicators meeting the customer's requirements. This project is one of the earliest high-speed stamping lines with independent intellectual property rights in China.

A factory in Nanjing has a project that requires updating and upgrading. The original production line is 70 meters long, and the equipment needs to be relocated to a new factory. However, due to insufficient space in the new factory, significant modifications to the structure of the existing automation equipment are required to ensure smooth installation and commissioning. After solving the problem with the press machine, the Haozhong team began to face the most difficult challenge in the project: space. Because the original production line is about 70 meters long, the new factory space can only accommodate a production line of about 58 meters. How can we save the extra dozen meters of space without sacrificing the performance of the production line?

The only solution to overcome difficulties lies in innovation. Ultimately, with the joint efforts of the team, Haozhong integrated the production line, which originally required the collaboration of several robotic arms, into three units. The first unit of the line integrates functions such as material loading and centering, and the visual centering part can achieve automatic centering. Moreover, the equipment at the beginning of the line has been updated. The middle unit of the line adopts a single-arm manipulator, matched with new manipulators at the beginning and end of the line, to achieve high-speed handling throughout the entire line. The end unit of the line adopts a newly developed material unloading robotic arm, which can achieve side-shifting and rotating functions, greatly shortening the layout length of the end part of the line. At the China Forging Association Automation Technology Seminar for Automotive Stamping, the achievements of Haozhong's Nanjing project were designated as a project for visiting and learning, and industry colleagues were all amazed!

On the path of localization, Haozhong measures every inch of distance from catching up to running neck and neck with sincerity. They use innovation as a blade to break through technological blockades, and service as a shield to safeguard the trust of local automakers. From the breakthrough of single-arm production line automation to the challenge of "impossible" space, Haozhong is not only polishing precision robotic arms, but also forging the solid backbone of China's automotive industry that is independently controllable. This persistence gives temperature to cold steel, and makes the blueprint of localization shine through every precise stamping and efficient operation.

In this issue, the "Powerful Nation, Smart Manufacturing" column recommends "Driving the Future" to you

Automation and intelligence are one of the directions for China's industrial development. However, in this process, we still face many problems. Besides technological innovation, upgrading old production lines is also a challenge we need to address. For example, in the automotive industry, equipment investment is already a significant expense. So, how can they achieve automated upgrading?

It is recommended to watch five minutes in advance

(If the channel broadcast time is adjusted, the new broadcast time shall prevail.)

The automotive industry serves as a crucial yardstick for assessing a country's comprehensive industrial strength during non-war times, reflecting its manufacturing capabilities and technological innovation. In recent years, as China's industrial level has continuously reached new heights, the development of the automotive industry has also ushered in a new chapter. The introduction of new energy vehicles and overtaking on the curve are our latest understandings of the domestic automotive industry. However, many are unaware that although domestic new energy vehicles have entered the international market, China's automotive industry's automation equipment manufacturing sector actually started relatively late, with overall development lagging behind the overall automotive manufacturing process level. Automated production lines are the backbone of the automotive industry. Stamping, as the foremost of the four major automotive manufacturing processes, has always been a manifestation of comprehensive technological strength, with the world's advanced level producing at a rate of more than 15 times per minute. This is no longer just a competition in manufacturing, but also an ultimate contest between countries' industrial systems, innovation ecosystems, and standard discourse power. Faced with difficulties, countless Chinese enterprises have stepped forward, marching towards this peak.

Hao Yuxin, the chairman of Jinan Haozhong Automation Co., Ltd., has been deeply involved in the field of automotive production line automation for nearly three decades. He is well aware of the urgent needs of domestic automobile companies. It is with this mindset that Haozhong, with innovation as its foundation and service as its compass, is moving forward towards the goal of developing domestically produced high-end production lines. At the beginning of its establishment, they set their development direction as high-speed stamping automation equipment systems. After long-term efforts by the team, coupled with joint development of the underlying control logic of high-speed robotic arms with a team of Tsinghua University Ph.D. students, they have overcome technical difficulties one by one and conducted extreme tests repeatedly. In 2014, they developed their first generation of high-speed single-arm robotic arm. Haozhong did not stop there, and in 2018, they successfully developed the second generation of high-speed single-arm robotic arm, with some performance indicators even surpassing the current international level. Instead of stopping, they continue to expand and optimize their products, providing the most suitable automation improvement solutions for domestic enterprises. This is the greatest benefit of domestic production.

After obtaining the relevant requirements and materials for the Kunshan project, Haozhong quickly returned to the company to conduct discussions. They comprehensively designed the project based on various aspects such as the customer's factory layout, production pace, and product characteristics, striving to come up with the most suitable solution for the customer. During this process, Haozhong's R&D team worked day and night, while continuing to optimize the dynamic model and motion curve trajectory of the robotic arm with a doctoral team from Tsinghua University. They pursued excellence and were determined to successfully fulfill the customer's requirements. On the other hand, Haozhong's core technical team mastered the underlying logic of the press's motion, which was more conducive to achieving the matching between the press and automation as well as the integration of the entire line. They had a deeper understanding of the mutual matching between automation and the press. Ultimately, the customer was moved by Haozhong's sincerity and signed an order in 2020. Haozhong also lived up to expectations, completing the installation and commissioning of the entire line in May 2021, with all operational indicators meeting the customer's requirements. This project is one of the earliest high-speed stamping lines with independent intellectual property rights in China.

A factory in Nanjing has a project that requires updating and upgrading. The original production line is 70 meters long, and the equipment needs to be relocated to a new factory. However, due to insufficient space in the new factory, significant modifications to the structure of the existing automation equipment are required to ensure smooth installation and commissioning. After solving the problem with the press machine, the Haozhong team began to face the most difficult challenge in the project: space. Because the original production line is about 70 meters long, the new factory space can only accommodate a production line of about 58 meters. How can we save the extra dozen meters of space without sacrificing the performance of the production line?

The only solution to overcome difficulties lies in innovation. Ultimately, with the joint efforts of the team, Haozhong integrated the production line, which originally required the collaboration of several robotic arms, into three units. The first unit of the line integrates functions such as material loading and centering, and the visual centering part can achieve automatic centering. Moreover, the equipment at the beginning of the line has been updated. The middle unit of the line adopts a single-arm manipulator, matched with new manipulators at the beginning and end of the line, to achieve high-speed handling throughout the entire line. The end unit of the line adopts a newly developed material unloading robotic arm, which can achieve side-shifting and rotating functions, greatly shortening the layout length of the end part of the line. At the China Forging Association Automation Technology Seminar for Automotive Stamping, the achievements of Haozhong's Nanjing project were designated as a project for visiting and learning, and industry colleagues were all amazed!

On the path of localization, Haozhong measures every inch of distance from catching up to running neck and neck with sincerity. They use innovation as a blade to break through technological blockades, and service as a shield to safeguard the trust of local automakers. From the breakthrough of single-arm production line automation to the challenge of "impossible" space, Haozhong is not only polishing precision robotic arms, but also forging the solid backbone of China's automotive industry that is independently controllable. This persistence gives temperature to cold steel, and makes the blueprint of localization shine through every precise stamping and efficient operation.