NEWS

A Glimpse into Stuttgart: A Summit Dialogue on Global Metalworking

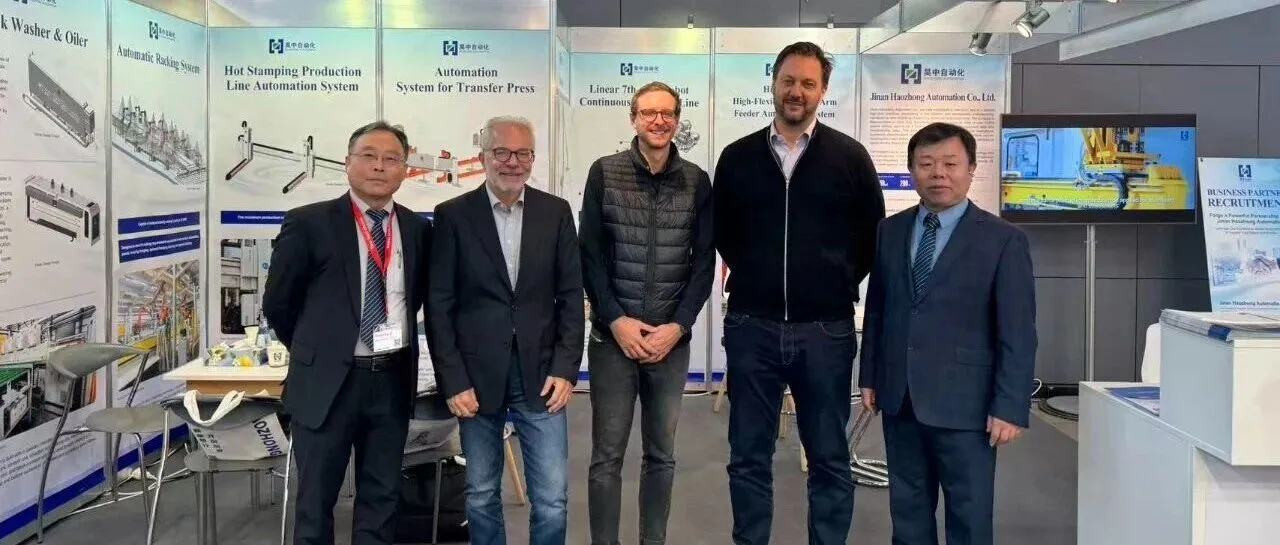

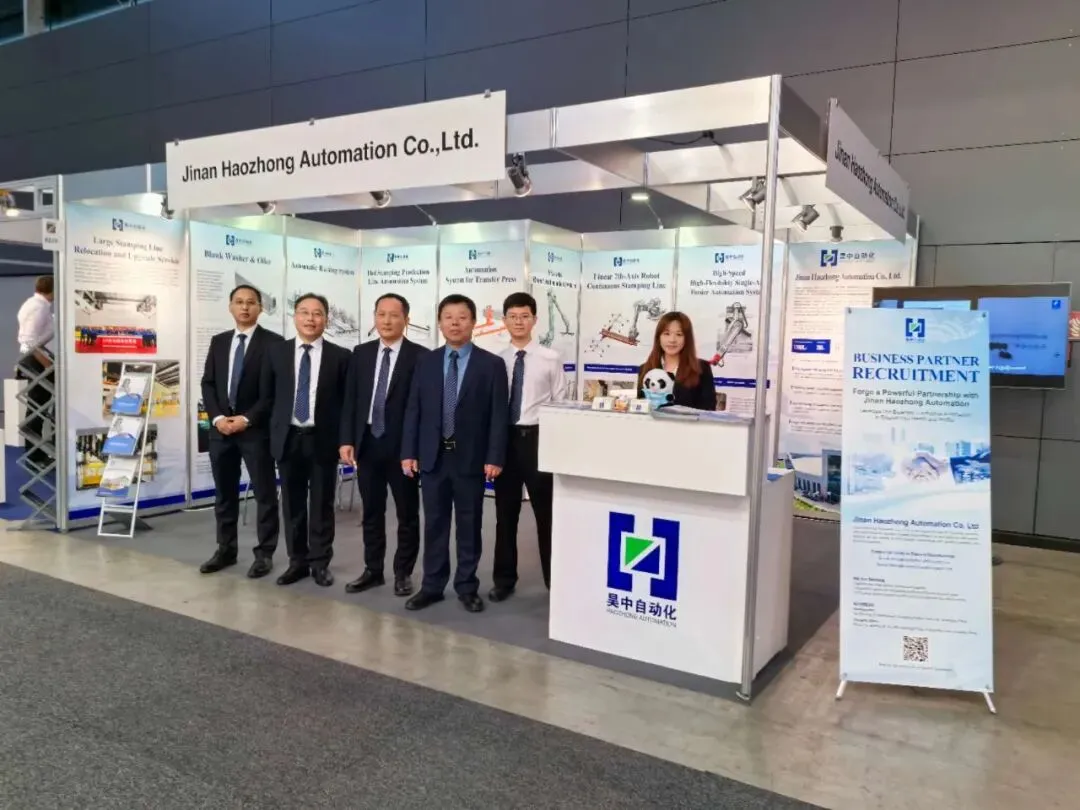

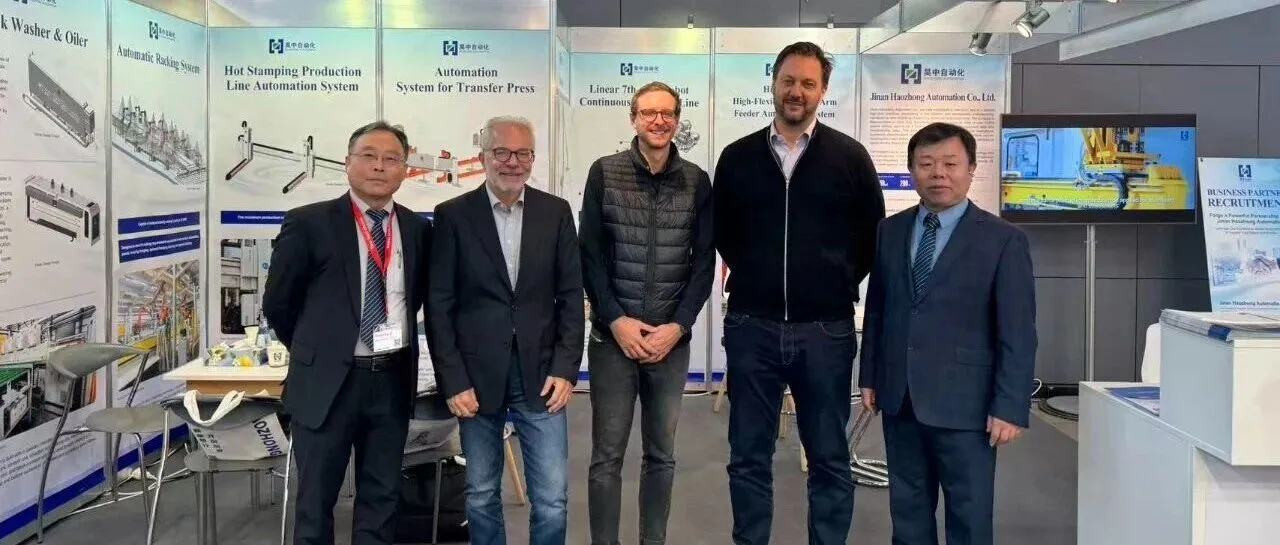

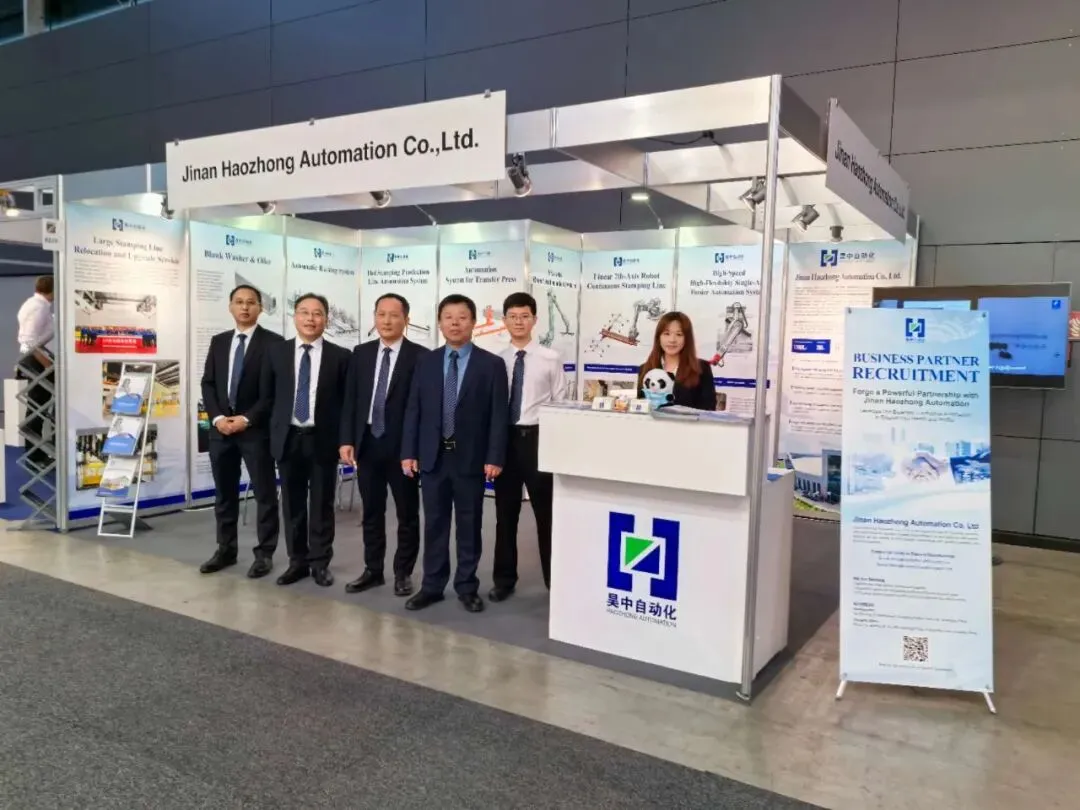

The four-day (October 21-24) Blechexpo 2025, a trade fair for sheet metal processing technology in Stuttgart, Germany, concluded on October 24 at the Stuttgart Exhibition Center. As a leading European trade fair for sheet metal processing, this year's event attracted over 1,000 exhibitors and more than 20,000 professional visitors from around the world. The booth of Jinan Haozhong Automation Co., Ltd. was consistently bustling with visitors, becoming a shining example of "Made in China" innovation.

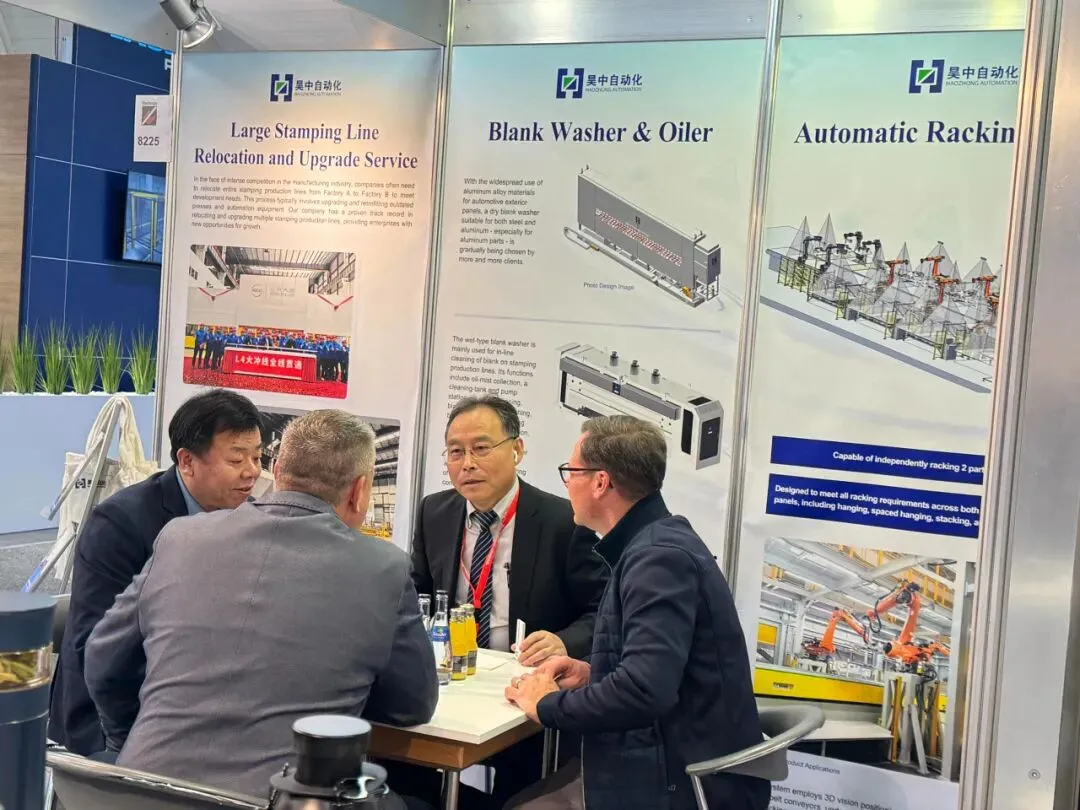

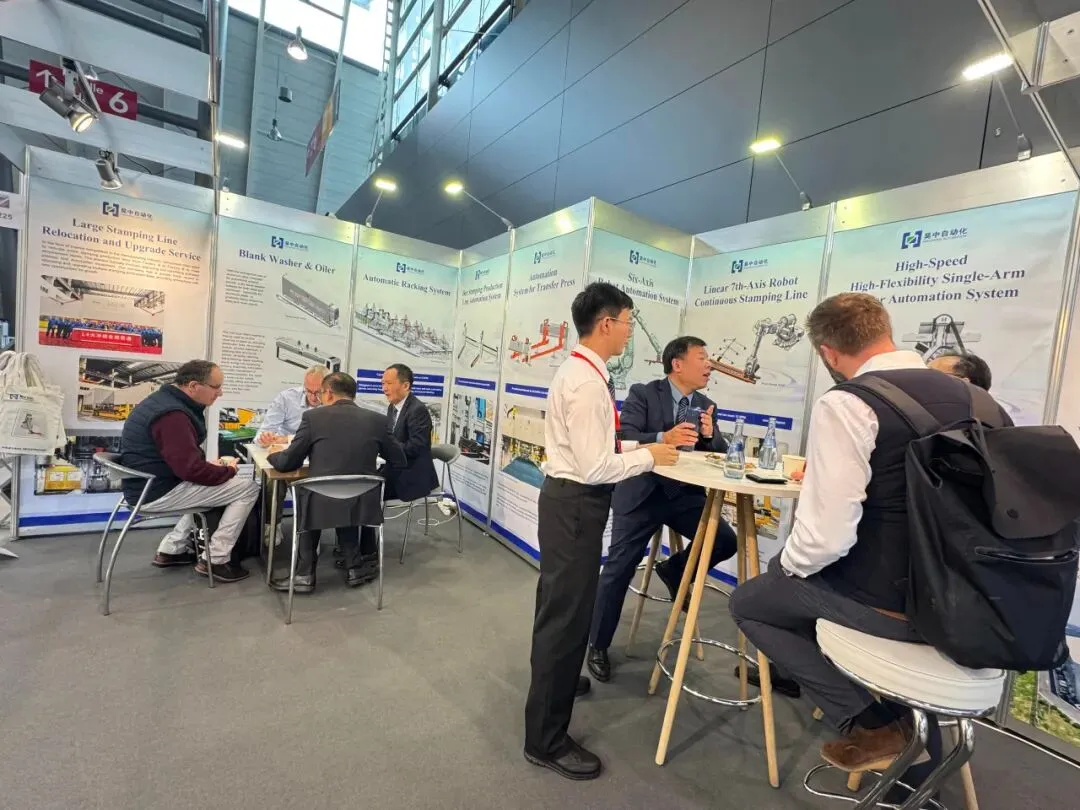

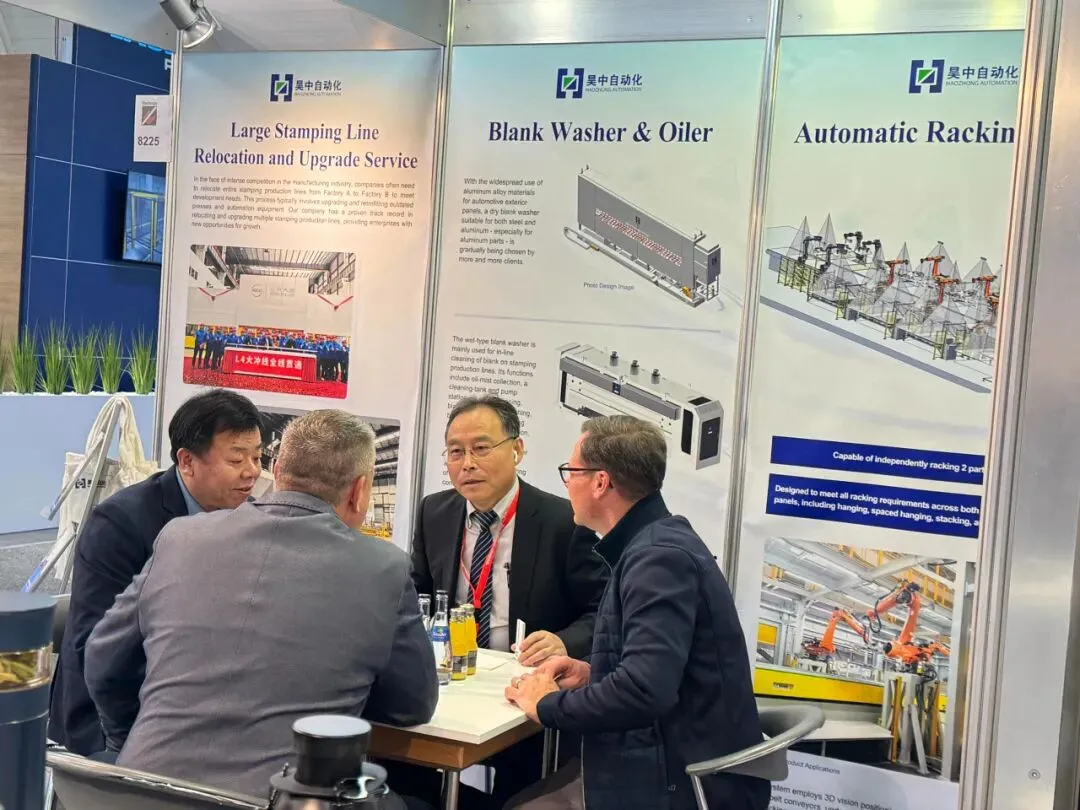

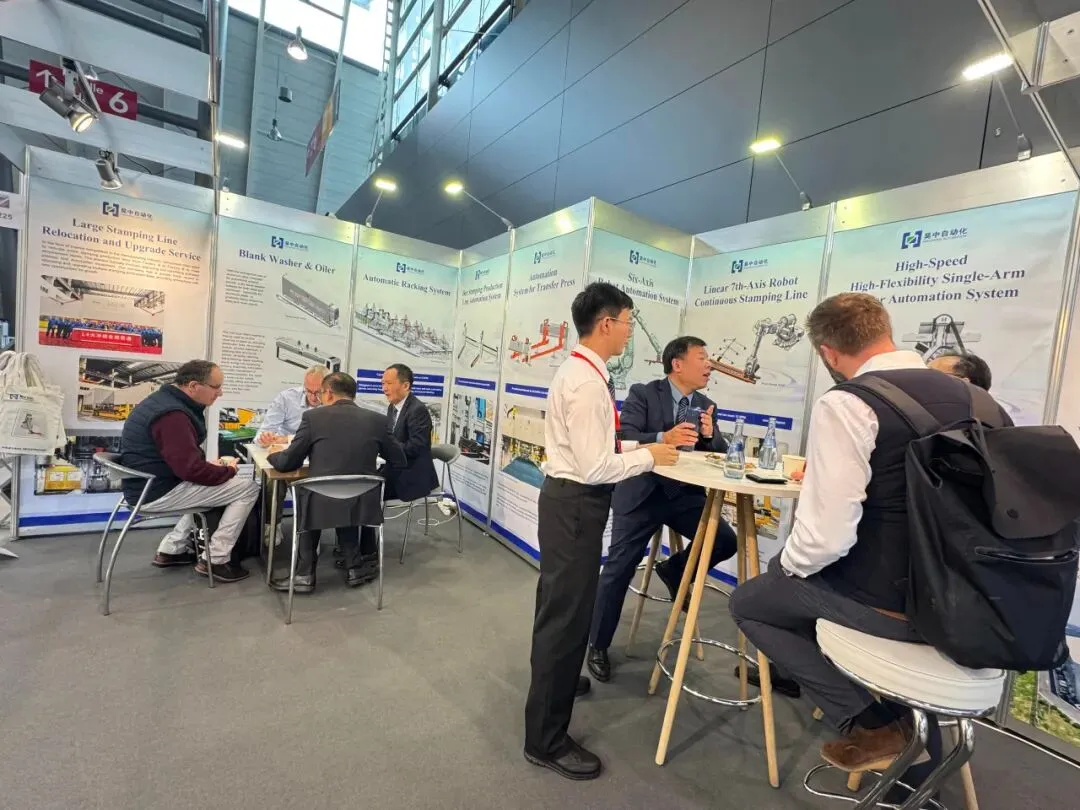

At the exhibition, Haozhong Automation's booth received over a hundred customers from Germany, France, Southeast Asia, and other regions, engaging in in-depth discussions on three core solutions: 1. Overall upgrade solution for stamping lines . Providing integrated "relocation + upgrade" services for the transformation of outdated equipment , successfully applied in numerous factories. 2. High-speed, high-flexibility single-arm robotic production line solution . This six-axis linkage high-speed, high-flexibility robotic arm, combined with our independently developed multi-axis linkage control system and a motion control system developed by a Tsinghua University PhD team, achieves a production cycle of 18 SPM , reaching international leading levels and perfectly adapting to the high-precision requirements of automotive stamping automation production lines . 3. End-of-line quality inspection + framing system solution . Integrating AI vision inspection technology, it can automatically identify defects, significantly improving the efficiency of defective product sorting, and is adaptable to various production lines.

On-site staff demonstrated the core advantages of the products in improving production efficiency and optimizing process control to visiting guests through technical demonstrations and case studies. The audience was full of praise after the demonstration.

Currently, automation, intelligence, and sustainability have become core development trends in the global sheet metal processing industry. Since its establishment in 2011, Haozhong Automation has been deeply involved in the field of stamping automation. Leveraging its strong R&D team and industry-academia-research collaboration advantages, many of its products have reached leading levels in China. Its appearance at Blechexpo 2025 not only allowed it to accurately grasp global industry technology trends but also, through in-depth exchanges with international peers, accumulated valuable resources for future technological innovation and market expansion.

Although the exhibition has concluded, Haozhong Automation's globalization efforts have not ceased. In the future, the company will continue to drive growth through technological innovation, continuously refine its high-end automation equipment products, strengthen international cooperation and technological exchange, and bring more high-quality "Made in China" solutions to the world!

The four-day (October 21-24) Blechexpo 2025, a trade fair for sheet metal processing technology in Stuttgart, Germany, concluded on October 24 at the Stuttgart Exhibition Center. As a leading European trade fair for sheet metal processing, this year's event attracted over 1,000 exhibitors and more than 20,000 professional visitors from around the world. The booth of Jinan Haozhong Automation Co., Ltd. was consistently bustling with visitors, becoming a shining example of "Made in China" innovation.

At the exhibition, Haozhong Automation's booth received over a hundred customers from Germany, France, Southeast Asia, and other regions, engaging in in-depth discussions on three core solutions: 1. Overall upgrade solution for stamping lines . Providing integrated "relocation + upgrade" services for the transformation of outdated equipment , successfully applied in numerous factories. 2. High-speed, high-flexibility single-arm robotic production line solution . This six-axis linkage high-speed, high-flexibility robotic arm, combined with our independently developed multi-axis linkage control system and a motion control system developed by a Tsinghua University PhD team, achieves a production cycle of 18 SPM , reaching international leading levels and perfectly adapting to the high-precision requirements of automotive stamping automation production lines . 3. End-of-line quality inspection + framing system solution . Integrating AI vision inspection technology, it can automatically identify defects, significantly improving the efficiency of defective product sorting, and is adaptable to various production lines.

On-site staff demonstrated the core advantages of the products in improving production efficiency and optimizing process control to visiting guests through technical demonstrations and case studies. The audience was full of praise after the demonstration.

Currently, automation, intelligence, and sustainability have become core development trends in the global sheet metal processing industry. Since its establishment in 2011, Haozhong Automation has been deeply involved in the field of stamping automation. Leveraging its strong R&D team and industry-academia-research collaboration advantages, many of its products have reached leading levels in China. Its appearance at Blechexpo 2025 not only allowed it to accurately grasp global industry technology trends but also, through in-depth exchanges with international peers, accumulated valuable resources for future technological innovation and market expansion.

Although the exhibition has concluded, Haozhong Automation's globalization efforts have not ceased. In the future, the company will continue to drive growth through technological innovation, continuously refine its high-end automation equipment products, strengthen international cooperation and technological exchange, and bring more high-quality "Made in China" solutions to the world!